EXPERTISE

CO-DESIGN

Specialized in realization of complex technical parts, the design office accompanies you upstream of your thinking to initiate and obtain the best mechanical characteristics without compromise of competitiveness.

MANUFACTURING

Committed in a process of continuous improvement since 2013, our factory is able to produce more than one million pieces per day in stamping, and 2,000 in deep drawing.

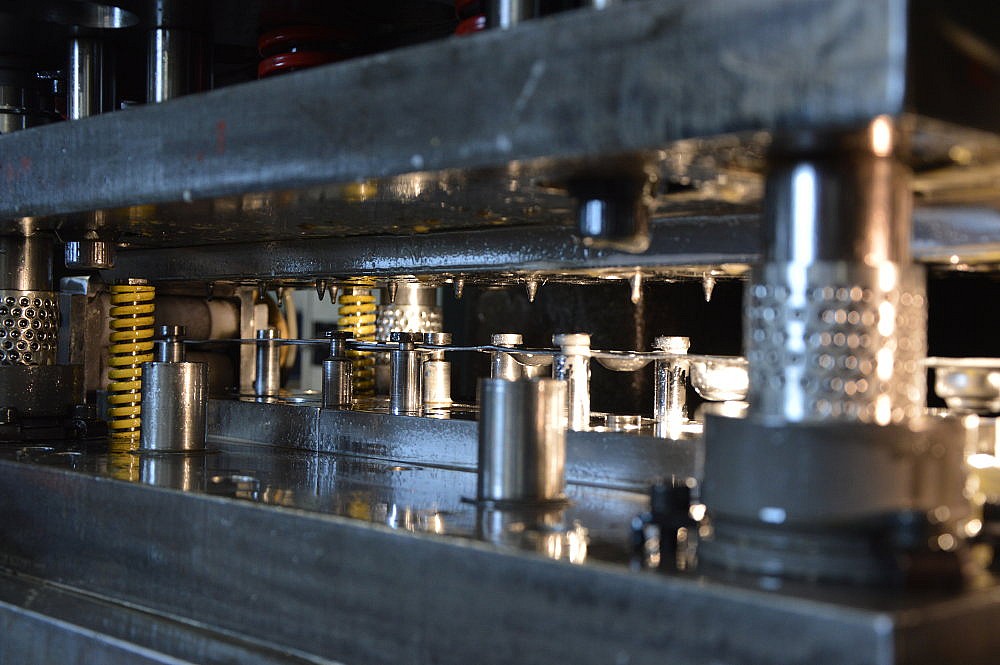

TOOLS

We design and carry out ourselves the plans, the assembly, the development and the industrialization of each new tools in order to always control the behavior of the tool during its serial life.

SERVICING

Whether in fineblanking,stamping or deep drawing, all our tools are maintained and improved internally, for incomparable responsiveness and optimization of tool life.

MEANS OF PRODUCTION

Organized in successive teams and using the tools of lean manufacturing since 2013, our factory is able to produce more than one million pieces per day in stamping, and 2,000 in deep drawing.

CUTTING

35 presses from 20 to 500 tons

THIN CUTTING

15 presses from 40 to 1100 tons

DEEP PACKING

5 presses from 50 to 400 tons

ASSEMBLY / WELDING

All types of finish